Efficient inventory management is critical in manufacturing and distribution, yet many companies still struggle with outdated processes. InHabitr, a leading AI-powered furnishing platform serving budget and luxury commercial real estate segments, faced significant operational challenges due to manual, paper-based inventory tracking.

InHabitr’s warehouses relied on manual processes that led to:

- Inefficient use of time for locating, picking, and shipping furniture.

- Frequent human errors in inventory audits and reconciliation.

- Delays in order fulfillment due to lack of real-time visibility.

- Increased operational costs from re-runs between warehouses and customer locations.

InThing’s RFID System

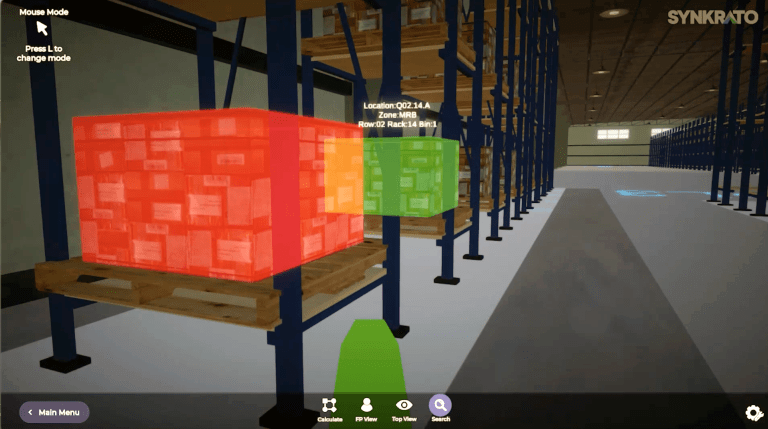

To overcome these challenges, InHabitr partnered with InThing to deploy an advanced RFID and barcoding solution. The implementation included:

- RFID and GPS tags for real-time inventory tracking.

- Handheld and fixed RFID readers for efficient scanning.

- InThing’s Returnable Inventory Solution for automated reconciliation.

A 6-week deployment timeline was followed, allowing for a seamless transition.

Deployment

The deployment followed a structured approach to ensure minimal disruption and smooth transition:

Assessment & Planning (Week 1-2)

- Conducted a warehouse audit to evaluate existing inventory workflows.

- Defined RFID implementation goals, such as reducing picking errors and improving real-time tracking.

- Designed a deployment roadmap, including necessary hardware and software components.

Hardware & Software Installation (Week 3-4)

- Installed fixed RFID readers and handheld scanners at key warehouse locations.

- Tagged inventory items with RFID and GPS labels for automated tracking.

- Integrated InThing’s Returnable Inventory Solution with existing warehouse management systems.

Testing & Training (Week 5)

- Ran pilot tests to validate system accuracy and troubleshoot any issues.

- Provided hands-on training for warehouse staff on using RFID scanners and monitoring inventory data.

Full Deployment & Optimization (Week 6)

- Rolled out RFID tracking across all operations.

- Conducted final system checks to ensure seamless functionality.

- Analyzed early performance data to fine-tune processes for maximum efficiency.

The Results

With RFID-powered automation, InHabitr achieved:

- 100% accurate inventory tracking—ensuring real-time visibility of furniture sets.

- Elimination of picking errors—improving order accuracy and reducing costly mistakes.

- Automated shipping & receiving validation—preventing incorrect shipments.

- Faster order fulfillment—reducing operational delays and improving customer

- Lower transportation costs & carbon footprint—by eliminating unnecessary re-runs between warehouses and customer locations.

Driving Efficiency with RFID

This success story highlights how RFID and barcoding technology can revolutionize warehouse operations. Companies like InHabitr can streamline operations, improve accuracy, and reduce costs by automating key processes.

RedLine Solutions, in partnership with InThing, delivers cutting-edge RFID and inventory management solutions tailored for manufacturing, distribution, and rental businesses. Want to see how your operation can benefit from RFID automation?